Motorcycle industries are following the lead of the automotive industry in utilizing more composite materials in the design of their vehicles. The benefits of reduced weight, increased performance, and improved fuel efficiency greatly outweigh the lower cost of traditional metals. Another benefit regarding the use of composites, especially carbon fiber, is the added “sex appeal” or improved visual appearance of the vehicle that showcases this high tech material. However, it is not always the OEMs (original equipment manufacturers) that lead the way in the use of composites. Aftermarket or specialty performance shops have found a niche market by creating composite parts to replace metal OEM parts.

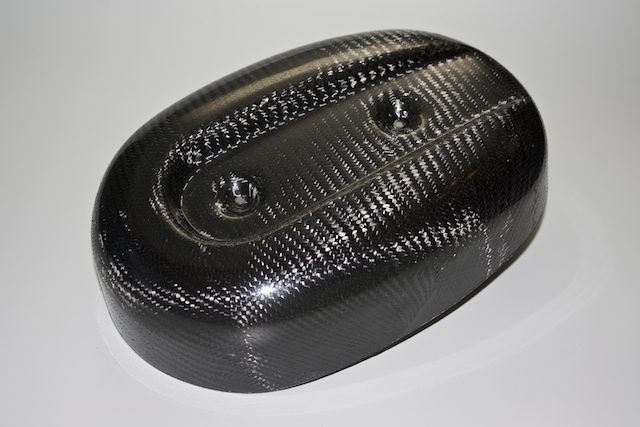

Osprey worked with one of these aftermarket performance companies to produce a composite replacement for the chrome plated steel air filter cover of a Harley Davidson motorcycle. The objective was to develop a carbon/epoxy cover that would be significantly lighter than the current metal cover. It was also designed to show off the high tech attractive appeal of a 2×2 twill carbon weave.

The design of the carbon fiber filter cover preserved the same form, fit, and function as the metal cover. Although this project was relatively straight forward, Osprey’s challenge with the composite filter cover was identifying the correct 2×2 twill area weight and orientation that would allow draping of the material without wrinkles or darting; this was a critical factor for the final visual appeal. The filter cover also had some areas of small radii, so bridging of the material was a concern. After several iterations, the preferred material, orientation, and layup process was developed, allowing us to produce an air filter cover that met our own company requirements. The final product produced a composite filter cover that was <25% the weight of the original steel cover.

Following the successful filter design, Osprey then worked with the company to identify various tooling and fabrication process options that could be optimized to more efficiently meet marketing sales predictions. Osprey is now working to identify other motorcycle parts that lend themselves to being replaced with composite materials.